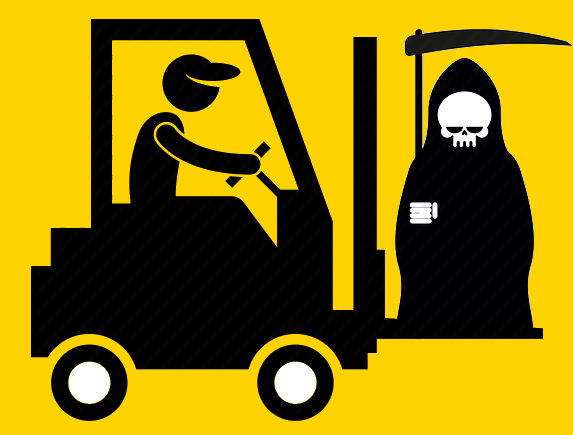

Too many forklift (fork truck / powered industrial truck) operators are heading to the next world early according to news headlines. The truth is that nearly all forklift fatalities are grizzly (traumatic for anyone who witnesses them) and in most cases 100% preventable.

Why are Forklifts so Dangerous?

They look like innocuous small machines, and it is relatively easy for anyone to get on and go forward. Yet, the average forklift weighs twice as much as an average car! It holds all its weight in the back (to counter the load) and steers for the rear, meaning it can skid out easily.

The physics behind how the truck handles also greatly changes depending on the weight and dimensions of the load been carried. It would be great if there was a ‘gravity need not apply here’ button, but it’s yet to be created. Gravity wins and humans that get in the way very quickly turn into meat packs.

What goes wrong?

Here are a selection of the latest stories and their key causes (remembering that there is never ONE reason that an incident happened).

Driver Line of sight Charges laid a year after forklift death:

June 15, 2017: Neilson St, Penrose A father of four, Herman Topui was killed on the job when he was run over by a container handler.

Speed and Line of Sight: Mother-of-seven Kamila Mun killed by forklift at first day of work on poultry farm:

Jun 16 2017, the incident occurred at Alderson Poultry Transport on a farm at Robinsons Rd, Broadfield, southwest of Christchurch. She died after being hit by a forklift at about 11.30am on Monday.

Unsecured Load, lack of pedestrian walkways Fatal interactions between forklifts and people:

September 2016 a Toll Networks (NZ) Limited a worker was crushed to death by falling pallets that were being moved from a train wagon by forklift

Lack of Training: Employee’s death in forklift accident results in $128,994 payout by Lower Hutt firm:

Dec 2015, Driver died after sustaining serious injuries to his torso when he became trapped between a cross beam on a racking unit and the console of the forklift he was operating.

Overloaded Machine Man crushed by forklift in accident:

12 Sep, 2011, a truck driver died at a TransDiesel when he was delivering a large generator. A forklift removing it from his truck toppled over, instantly crushing him to death.

What Causes Forklift Fatalities?

- Rollover: Due to load instability, overload, uneven flooring or changes to incline/direction of travel. This is especially scary because it happens so quickly. Once the load moves outside a certain centre of gravity, it all goes wrongs wrong in a matter of seconds.

- Collisions: This occurs because the driver doesn’t understand the breaking distances required when driving a loaded forklift. These breaking distances are logarithmic (like the earthquake Richter scale) as the load and speed increase, the distance required to brake safely increases exponentially.

Minimum Actual Emergency Stopping Distance

Speed (km/h) 6 12 14 16 18 20 22

Minimum Emergency 2.9-3.2 7-8 8-10 9.5-12 11-14 13-16.5 14.5-19

Stopping Distance (m)

Monash University Accident Research Centre findings on emergency braking distances for typical forklifts on a level surface – based on a driver reaction time of 1.5 seconds.

- Lack of Driver Training: Operators do not have the correct endorsements, training or familiarisation with the machine they are using. Remembering that LPG, electric, diesel and petrol trucks all have their own idiosyncrasies and the driver needs to understand what the load plate means and the truck’s capabilities.

- Site Set Up & Environment: Lack of designated pedestrian walkways, limited line of site and changes to weather conditions can all play a role in forklift fatalities.

- Maintenance: Lack of pre-start checks and scheduled maintenance means things like spongy breaks, loose chains and unresponsive hydraulics are not dealt with

What can you do to keep your team safe?

- Set your site up to minimise the interaction between pedestrians and forklifts

- Ensure operators are trained and familiarised with your forklifts

- Ensure operators do pre-operations checks and regular preventative maintenance is carried out

If you are confused, take a read of these:

- Approved Code of Practice (ACOP) for training operators and instructors of powered industrial lift trucks (forklifts).

- Safety Code for Forklift Truck Operators No.1 Front Loading Forklift Trucks

- Forklifts and carbon monoxide poisoning

Have a safe and productive week and I genuinely hope that I never have to discuss forklift fatalities at your site.

SB